Contact Us

Engineering excellence in mechanical systems, manufacturing, and innovation with 60+ years of academic legacy

4 Years

8 semesters of comprehensive mechanical engineering education with industry exposure

10+2 PCM

Physics, Chemistry, and Mathematics with minimum 50% aggregate marks

Full-time

Campus-based program with hands-on laboratory sessions and industrial training

English

All courses taught in English with comprehensive study materials and resources

Updated syllabus aligned with current industry standards, covering traditional mechanical engineering fundamentals and emerging technologies like additive manufacturing, Industry 4.0, and sustainable energy systems.

Learn from experienced professors with Ph.D. qualifications, extensive industry experience, and active research in areas like thermal engineering, design optimization, and advanced manufacturing technologies.

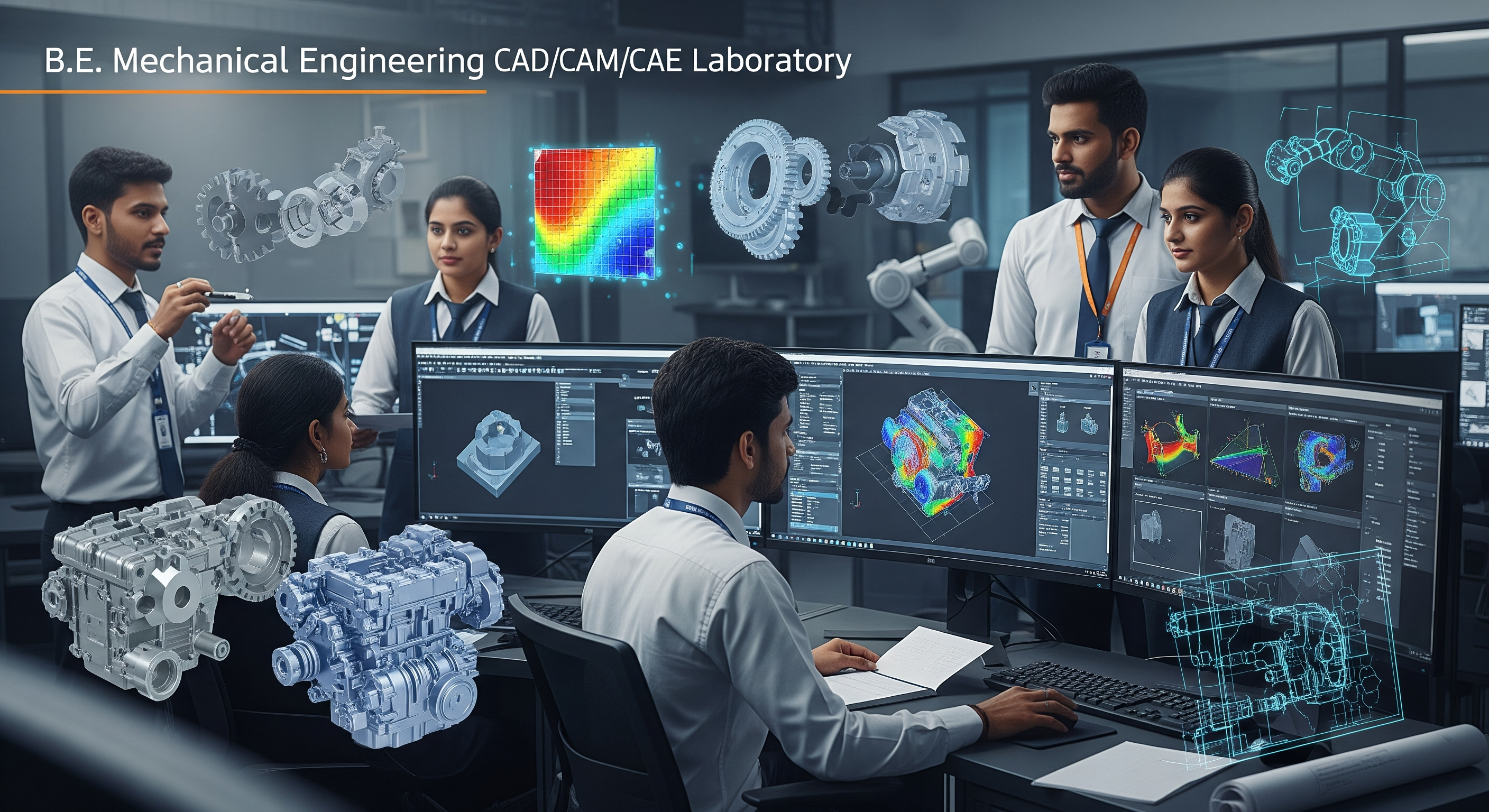

State-of-the-art laboratories including CAD/CAM, CNC machining, thermal engineering, fluid mechanics, manufacturing processes, and robotics labs with latest equipment and software tools.

Active research culture with projects funded by government agencies. Students participate in conferences, publish papers, and work on cutting-edge technologies in renewable energy, automotive systems, and smart manufacturing.

Strong partnerships with leading automotive, aerospace, manufacturing, and energy companies. Regular industry visits, guest lectures, internships, and live projects provide real-world exposure and networking opportunities.

Dedicated placement cell with 95% placement record. Training in aptitude, soft skills, technical interviews, and resume building. Top recruiters include Tata Motors, Ashok Leyland, TVS, Mahindra, L&T, and MNCs.

MA1101

Engineering Mathematics - I

4 Credits

PH1101

Engineering Physics

4 Credits

CY1101

Engineering Chemistry

4 Credits

GE1101

Problem Solving and Python Programming

4 Credits

ME1101

Engineering Graphics

4 Credits

GE1111

Physics and Chemistry Laboratory

2 Credits

GE1112

Python Programming Laboratory

2 Credits

GE1113

Engineering Practices Laboratory

1 Credits

MA1201

Engineering Mathematics - II

4 Credits

PH1201

Materials Science

3 Credits

BE1201

Basic Electrical and Electronics Engineering

4 Credits

GE1201

Engineering Mechanics

4 Credits

GE1202

Environmental Science and Sustainability

3 Credits

ME1201

Computer Aided Drafting and Modelling

4 Credits

GE1211

Electrical and Electronics Laboratory

2 Credits

GE1212

CAD Laboratory

1 Credits

Focus on heat transfer, refrigeration and air conditioning, power plant engineering, combustion technology, and sustainable energy systems. Ideal for careers in energy sector, HVAC industry, and power generation companies.

Specialize in machine design, finite element analysis, CAD/CAM/CAE tools, product development, and optimization techniques. Pursue careers in automotive design, aerospace engineering, and product development companies.

Advanced manufacturing processes, CNC machining, automation, quality control, production planning, and Industry 4.0 technologies. Opportunities in manufacturing industries, production management, and operations.

Vehicle dynamics, engine design, automotive electronics, electric vehicles, hybrid technology, and autonomous systems. Career paths in automotive companies, EV startups, and vehicle testing facilities.

Industrial robotics, programmable logic controllers, mechatronics, sensors and actuators, and intelligent manufacturing systems. Work in automation companies, robotics startups, and smart manufacturing units.

Renewable energy technologies, solar thermal systems, wind energy, energy management, green building systems, and sustainable engineering solutions. Careers in renewable energy sector and environmental consulting.

Design and develop mechanical systems, components, and products using advanced CAD software. Work on innovative solutions for automotive, aerospace, and industrial machinery applications.

Manage manufacturing processes, optimize production lines, implement quality control measures, and improve efficiency. Essential role in automotive, FMCG, and heavy industries.

Ensure product quality through testing, inspection, and adherence to standards. Implement quality management systems and continuous improvement methodologies in manufacturing environments.

Design, develop, and test vehicles and vehicle systems. Work on engine design, vehicle dynamics, safety systems, and emerging technologies like electric and autonomous vehicles.

Develop 3D models, engineering drawings, and manufacturing programs using advanced software. Bridge the gap between design and manufacturing in product development companies.

Plan and execute preventive and corrective maintenance of industrial equipment. Minimize downtime, extend equipment life, and ensure smooth operations in manufacturing facilities.

Conduct research, develop new technologies, and innovate products. Work in advanced technology domains like additive manufacturing, materials science, and sustainable engineering.

Lead engineering projects from conception to completion. Manage teams, budgets, timelines, and stakeholders in manufacturing, construction, and infrastructure projects.

LGB

Foxconn

TVS Group

Sourcesys

Infinix

Pronoia Insurance

State-of-the-art computer lab equipped with AutoCAD, SolidWorks, CATIA, Mastercam, ANSYS, and other industry-standard software for design, analysis, and manufacturing simulation.

Advanced lab with multi-cylinder diesel engines, refrigeration systems, air conditioning trainers, boiler setup, and heat transfer equipment for practical thermal engineering experiments.

Comprehensive fluid mechanics lab featuring various pumps, turbines, flow measurement devices, pipe networks, and hydraulic machines for hands-on learning of fluid dynamics principles.

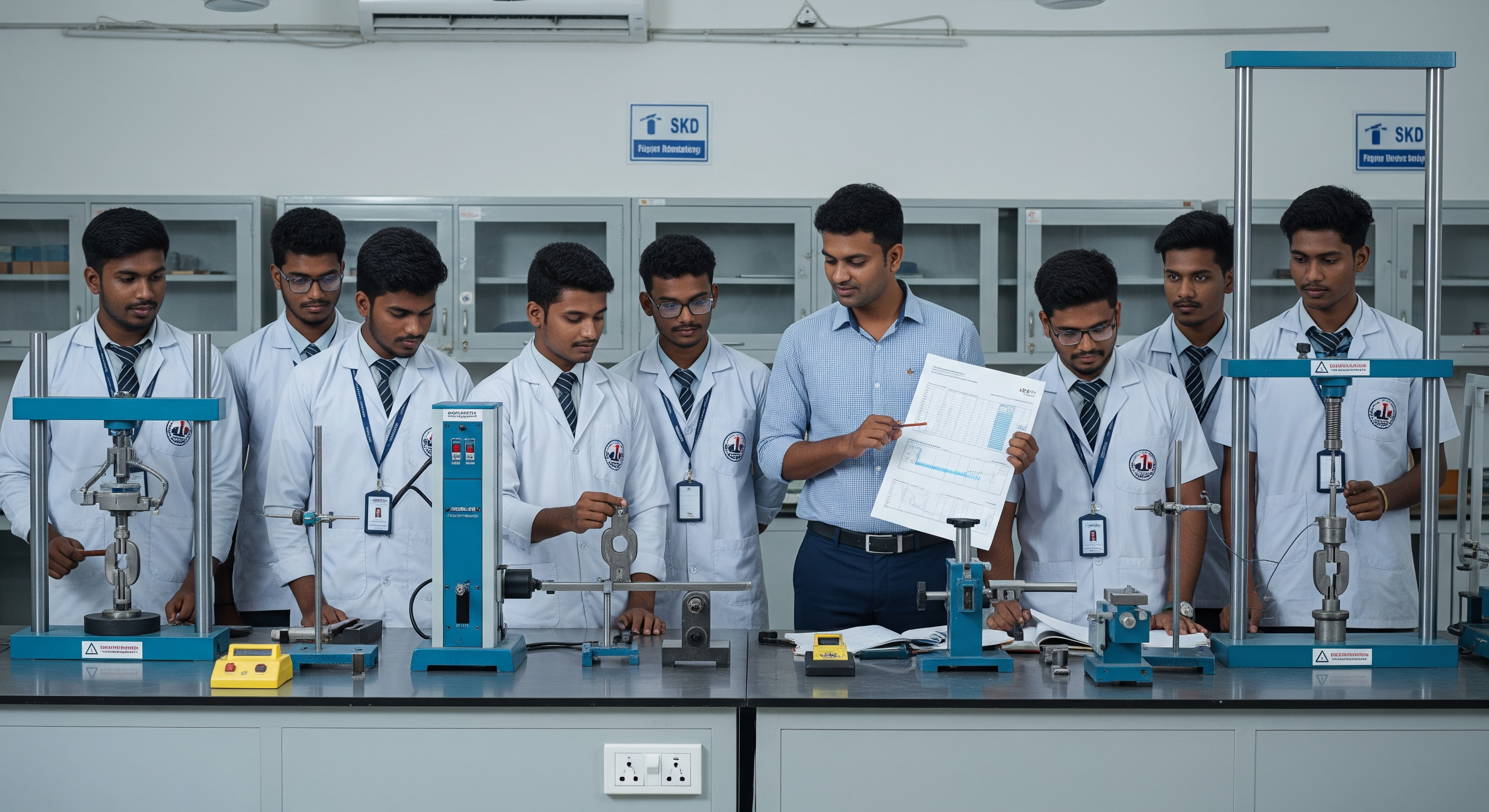

Well-equipped lab with universal testing machine, impact testing machine, hardness testers, torsion apparatus, and beam testing setups for material properties analysis and testing.

Modern manufacturing lab with CNC machines, lathe, milling, welding, casting equipment, and precision measuring instruments for practical training in various manufacturing processes.

.png)

Cutting-edge lab with industrial robots, PLC trainers, pneumatic and hydraulic circuits, sensors, actuators, and automation equipment for Industry 4.0 skill development.

Professor & Head

Ph.D. (Thermal Engineering)

Heat Transfer, Renewable Energy Systems

Professor

Ph.D. (Manufacturing Engineering)

CNC Machining, Advanced Manufacturing

Associate Professor

Ph.D. (Design Engineering)

FEA, Machine Design, CAD/CAM

Associate Professor

Ph.D. (Automobile Engineering)

Vehicle Dynamics, Electric Vehicles

Assistant Professor

M.E. (Manufacturing)

Production Planning, Quality Control

Assistant Professor

M.E. (Energy Engineering)

Solar Energy, Sustainable Engineering

Assistant Professor

M.E. (CAD/CAM)

Computer Aided Design, Solid Modeling

Assistant Professor

Ph.D. (Thermal Sciences)

Combustion, IC Engines, CFD

Ensure you have passed 10+2 with Physics, Chemistry, and Mathematics with minimum 50% aggregate marks (45% for reserved categories). Age should be minimum 17 years.

Complete the online application form on our admission portal with accurate details. Upload required documents including mark sheets, transfer certificate, and community certificate if applicable.

Qualify in TNEA counseling (Tamil Nadu students) or appear for JEE Main / Institution entrance test. Merit-based selection for eligible candidates based on entrance exam scores.

Attend counseling session with original documents for verification. Receive provisional allotment letter and complete the admission formalities with fee payment.

Pay the admission fee online or at the college. Receive admission confirmation, student ID, and joining instructions. Report to college on the specified date for orientation.

Students placed in reputed companies

Competitive salary packages

Offered by leading MNC

Companies participated

Join JKKN College of Engineering and build a successful career in Mechanical Engineering with industry-relevant skills and world-class education.